Erkilet Quarry

Basalt: Properties of Natural Stone

Basalt is a natural stone that has been prominent in people’s choice of building materials for centuries. Basalt stone, known for its hardness, durability and aesthetic appearance, is widely preferred in the construction industry. We will explore the “Journey of Basalt“, which is carried out using the machines in our STONEXPORTER Basalt Quarry and STONEXPORTER Basalt Production Facility, located in Kayseri, which is rich in underground resources.

Processing Process

Basalt is formed by the rapid cooling of magma formed as a result of volcanic activity. The density and purity of this natural stone are the most important reasons why it is preferred in the field of building materials. Our STONEXPORTER Basalt Quarry and STONEXPORTER Basalt Production Facility located in Kayseri are equipped with advanced machines to process this precious stone.

Transition from Quarry to Factory

Operation of the Quarry

The first step is to remove the rocks from the quarry. In general, Basalt Quarries are places where natural rocks that maintain their purity are extracted. Our quarry equipment includes Excavator, Loader, Truck and Trailer. The dismantling process of Basalt Rocks is carried out using the excavator. Again, by bringing them to the appropriate shape and tonnage using the excavator, the ready-for-cutting production of Basalt Blocks is achieved. Basalt Blocks are loaded onto a truck or trailer via a loader and begin their journey to our production facility.

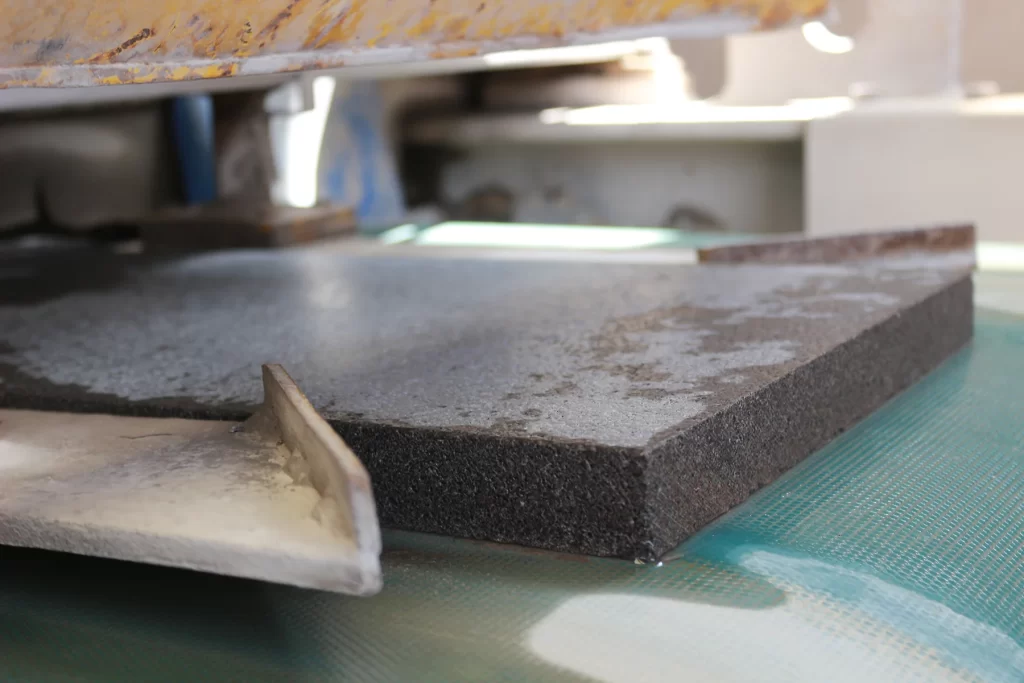

Cutting of Basalt Slabs

Solid and high-quality Basalt Blocks, carefully produced at this stage, form the basis of the production process. ST Machine located in our Basalt Production Facility is an equipment used for cutting process. This machine helps us extract basalt, which is mined in large blocks, in the form of slabs. Basalt blocks thanks to diamond-tipped saws; Cut carefully, quickly and effectively. As a result of the cutting process with the ST machine, the short side surfaces are produced in the form of amorphous Basalt Slabs.

Processing of Basalt Slabs

Beheading Machine; It enables the cut Basalt Slabs to be processed according to the desired orders and more precise measurements. Head Cutting machine enables cutting the edge surfaces of Basalt Slabs created by the ST machine to the desired dimensions. Beheading Machine makes the edge surfaces smooth and sharp. As a result of the production of the Beheading Machine, the first production phase of Basalt Flooring and Covering stones is realized.

Erkilet Factory

Polishing Machine is used to increase the aesthetic appearance of basalt. This machine ensures that the basalt has a desired surface finish and at the same time maintains its natural texture. The natural beauty of basalt is revealed with abrasive, brush and sandblasting devices applied to the surface of basalt. As a result of the production with these apparatus, Polished Basalt, Brushed Basalt, Hammered Basalt, Honed Basalt are produced. The surface treatment stage provides an aesthetic contribution to basalt construction projects.

Providing Aesthetic Appearance

Facing-Polishing-Chamfering Machine provides an aesthetic appearance to the basalt stone by opening the chamfers and profiles of the basalt plates produced with the beheading machine. The basalt stone produced as a result of this machine has an important role, from exterior cladding to the preparation of stair stones. The chamfering process ensures that basalt edge surfaces are shaped appropriately within the scope of the desired application. This machine also gives the basalt stone an aesthetic appearance by polishing the surface of the chamfered or profiled basalt plate.

Breaking in Natural Shapes

One of the most remarkable stages of basalt production is carried out using a Blasting Machine. Blasting using a Blasting Machine ensures that the basalt is broken into natural shapes. This method, performed with this machine, is especially appreciated in decorative stone applications and landscaping. The blasting process is an important stage that reveals the naturalness and unique appearance of basalt.

The journey of basalt is an adventure where the purity and durability of natural stone is revealed. STONEXPORTER; With its Basalt Quarry and Basalt Production Plant, it is an excellent source to deliver high quality and customized basalt products. Its machines and experienced team maximize the potential of natural stone.

Use of Basalt

Basalt offers a versatile use in the construction industry. It is preferred in road coverings, exterior coverings, landscaping, interior designs and many other areas. Its durability and aesthetic appearance add value to your buildings. The journey of basalt is an impressive adventure that reveals the purity and durability of natural stone. At StonExporter, we are here to offer quality and customized Basalt products.

Journey's End

By working with us, you can combine your projects with the beauty and durability of natural stone. If you would like to get more information or review special Basalt products for your projects, please continue to visit our website. As StonExporter, we are here to provide the best solutions for you.